The DN100 compressed air vortex flowmeter works based on the Kamen vortex principle, whereby when compressed air flows through a vortex generator in the flowmeter (bv. a column or a specific geometry), draaikolke word afwisselend aan beide kante daarvan gegenereer. The separation frequency of these vortices is directly proportional to the flow rate through the generator, so by detecting the separation frequency of the vortices, the compressed air flow rate can be calculated.

DN100 compressed air vortex flowmeter is widely used in various industrial occasions which need to measure compressed air flow, such as pneumatic control system, compressed air supply system, pneumatic tools and equipment. By measuring compressed air flow, precise control and monitoring of pneumatic systems can be realized to improve production efficiency and quality.

| Produk | DN100 saamgeperste lug draaikolk vloeimeter |

| Model | Meacon-LUGB |

| Nominale deursnee | DN100 |

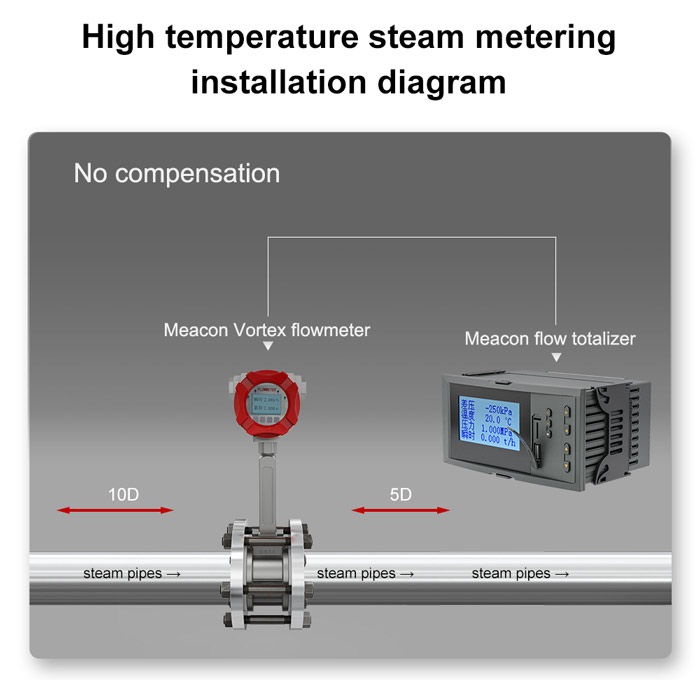

| Installasie | Wafer verbinding: DN10-DN500(prioriteit PN2.5MPa) Flensverbinding: DN10-DN80(prioriteit PN2.5MPa);DN100-DN200(prioriteit PN1.6MPa);DN250-DN500(priority PN1.0MPa) |

| Akkuraatheid | 1.5%, 1.0% |

| Reeksverhouding | 8:1 |

| Medium Temperatuur | -20°C ~ +150°C, -20°C ~ +260°C, -20°C ~ +320°C, -20°C ~ +420°C |

| Uitset sein | 4-20mA |

| Frekwensie | RS485 communication (Modbus RTU) |

| Kragtoevoer | 24VDC±5% Li-battery(3.6VDC) |

| Indringende beskerming | IP65 |

| Liggaamsmateriaal | Vlekvrye dop |

| Vertoon | 128*64 puntmatriks LCD |

DN100 compressed air vortex flow meter is widely used in a variety of occasions where compressed air flow needs to be measured, soos:

DN100 compressed air vortex flowmeter has many advantages and a wide range of application scenarios, in the selection and use of matters needing attention to ensure its accuracy and stability.

When choosing a DN100 compressed air vortex flowmeter, you need to pay attention to the following points:

When choosing DN100 compressed air vortex flowmeter, you need to consider the characteristics of the measuring medium (such as temperature, druk, density, ens.), measuring range, accuracy requirements, the use of the environment and the installation conditions and other factors. Terselfdertyd, you also need to choose a reliable manufacturer and brand to ensure the quality of the meter and after-sales service.

Ons waardeer u terugvoer! Vul die onderstaande vorm in sodat ons ons dienste by u spesifieke behoeftes kan aanpas.

INQUIRY