Flange Mounted Roj Chav Vortex Flougeter

Flange mounted vortex flowmeter for gas vapors need to choose the right model, follow the correct installation procedure, pay attention to the installation location and straight pipe section requirements, and regular inspection and maintenance. Meanwhile, it is widely used in many industries, providing reliable flow measurement solutions for industrial production. Steam vortex flowmeters have a wide range of applications in several industries, such as:

- Energy industry: Used to measure boiler feedwater and steam flow in thermal power plants, nuclear power plants and other energy facilities.

- Chemical industry: Measure the flow of various corrosive, high temperature and high pressure fluids.

- Metallurgical industry: Measures the flow of fluids such as blast furnace gas and air.

- Food Industry: Measures the flow of fluids such as steam and hot water to ensure hygiene and safety in food processing.

Tham OnlineTiv tauj peb

Flange mounted gas steam vortex flowmeter mainly involves the selection of flowmeter, installation steps, precautions and application scenarios. The following are detailed answers to these questions:

Txoj Cai Ua Haujlwm

Based on the Kamen vortex principle, i.e. the vortex separation frequency is proportional to the flow rate. When the measured medium flows through the vortex generator inside the flowmeter, vortices are generated alternately on both sides of it, and the flow rate is calculated by measuring the frequency of vortex generation.

Specificities

Simple and solid structure, no moving parts, kev ntseeg siab; simple installation, easy maintenance; stable output signal, high precision; wide measuring range, large range ratio; me me poob siab, low operating costs.

Scope ntawm daim ntawv thov

Suitable for measuring the volume flow and mass flow of steam, gases and liquids, especially suitable for flow measurement of steam media fluids in industrial pipelines.

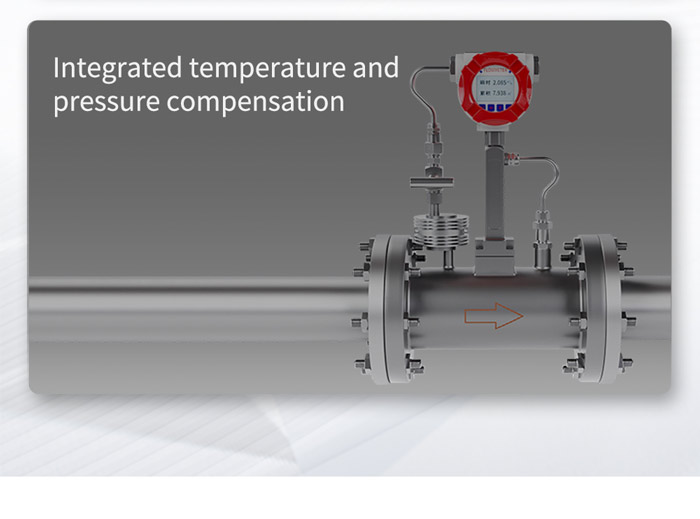

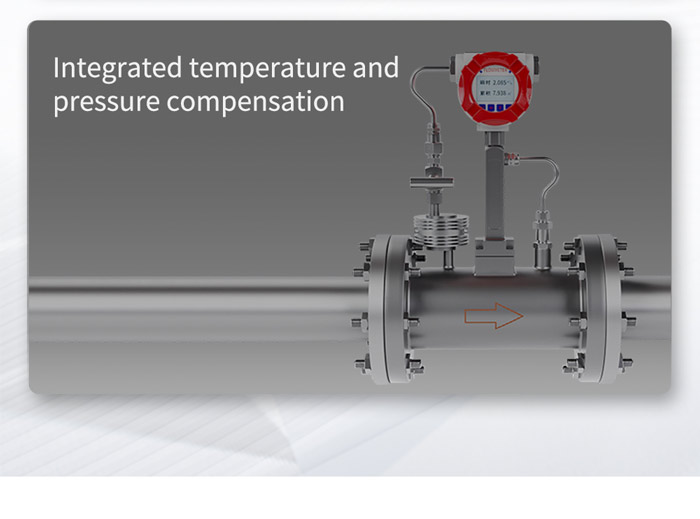

For flange-mounted gas steam vortex flowmeter, you need to choose the model with a flange connection interface, such as Weifang Aobo Instrumentation produced LUGB steam thermal oil flange-mounted gas vortex flowmeter, with a nominal diameter range of DN15-DN600, nominal pressure of up to 2.5MPa or 4.0MPa, the media temperature of up to 0-350 ° C, able to meet the majority of industrial application of the It can meet the needs of most industrial applications.

Installation steps

- 1. Preparation: Check whether the specification, model and material of the flowmeter and flange meet the requirements; clean the sealing surface of the flange to ensure that there are no radial scratches, serious corrosion, deformation and other defects; prepare the tools required for installation, such as torque wrenches, sealing gaskets and so on.

- 2. Mounting flange: Connect the flange to the pipeline or equipment to ensure that the flange parallelism, concentricity, tension, tus lwm yam. meet the requirements. In accordance with the flange bolt torque tightening sequence, tighten the bolts one by one in 2 to 3 times until the final tightening torque value is reached.

- 3. Install the flow meter: Match the flowmeter flange with the pipe flange to ensure that the flange sealing surfaces are in good contact. Insert a sealing gasket between the flanges, noting the orientation and position of the gasket. Tighten the bolts between the flow meter flange and the pipe flange to ensure a solid connection.

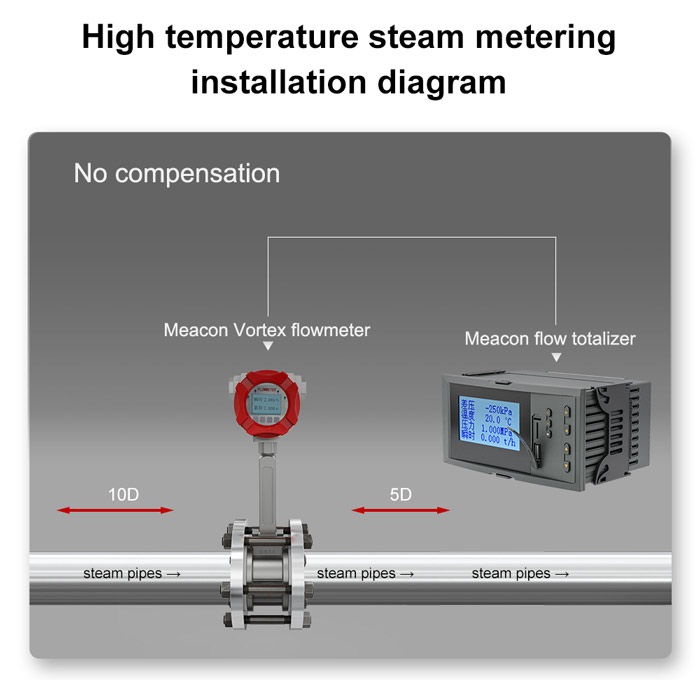

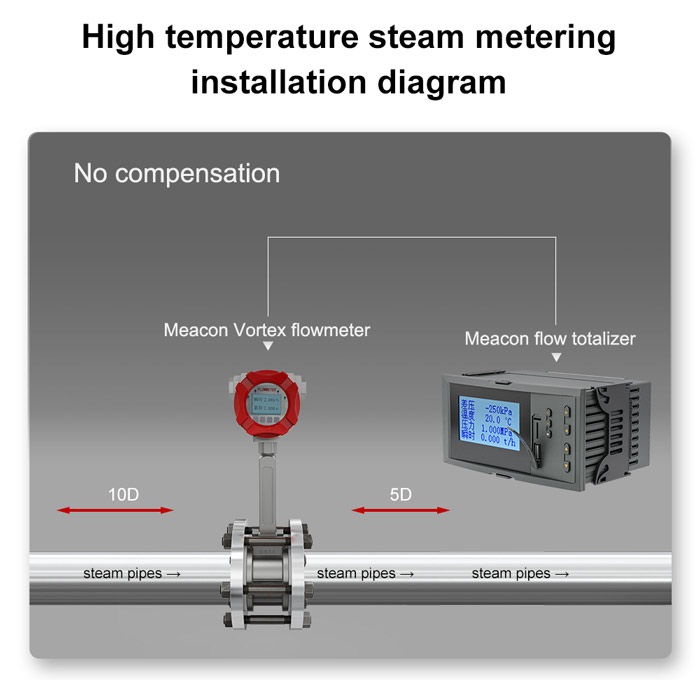

- 4. Inspection and commissioning: Check whether the installation location of the flowmeter meets the requirements, avoid installation in a strong electromagnetic field, strong mechanical vibration, prone to lightning strikes and the use of conditions do not match the temperature and humidity environment. Check that the length of the upstream and downstream straight pipe sections of the flowmeter is sufficient to ensure measurement accuracy. Commission the flowmeter and check whether its output signal and measured value are normal.

Caveat

- 1. Mounting location: The flowmeter should be installed in a location where it is easy to observe, maintain and overhaul, and avoid installing it in a place with high vibration and strong interference.

- 2. Straight pipe segment requirements: The length of the upstream and downstream straight pipe sections of the flowmeter should meet the requirements to ensure the measurement accuracy.

- 3. Temperature and pressure: Note whether the temperature and pressure of the measuring medium are within the permissible range of the flow meter.

- 4. Regular inspection and maintenance: Regularly check whether the connection of the flowmeter is leaking and whether the wire contact is good; regularly clean the accumulated dirt and impurities inside the flowmeter to maintain its measurement accuracy and stability.

INQUIRY