Meacon steam gas 4-20mA vortex flowmeter is a kind of flow measurement instrument designed based on Karmen vortex principle, which is widely used in the flow measurement of medium (including steam and gas) in industrial pipeline.

Meacon steam gas 4-20mA vortex flowmeter determines the flow rate by measuring the frequency of vortices generated by the fluid inside the flow sensor. When the fluid flows through the flow sensor, regular vortices are generated alternately on both sides of the vortex generator, and the frequency of these vortices is proportional to the fluid flow rate, so that the flow rate can be calculated.

| Product | Meacon steam gas 4-20mA Vortex flowmeter |

| Model | SUP-LUGB |

| Diameter nominal | DN15~DN300 |

| Installation | Wafer connection: DN15-DN300(priority PN2.5MPa); Flange connection: DN15-DN50(priority PN2.5MPa);DN65-DN200(priority PN1.6MPa);DN250-DN300(priority PN1.0MPa) |

| Accuracy | Gas without compensation: DN15-DN25–1.5%, DN32-DN200–1.0%, DN250-DN300–1.5% |

| Range Ratio | Gas density:1.2kg/m3, Range ratio: 8:1 |

| Medium Temperature | -20°C ~ +150°C、-20°C ~ +260°C、-20°C ~ +300°C |

| Sinjali i daljes | 4-20mA |

| Frequency | RS485 communication (Modbus RTU) |

| Power supply | 24VDC±5% Li battery(3.6VDC) |

| Ingress protection | IP65 |

| Body Materials | Stainless shell |

| Display | 128*64 dot matrix LCD |

4-20mA is a commonly used analog signal that indicates the size of the measured value by the magnitude of the current. In vortex flowmeter, 4mA indicates the minimum value and 20mA indicates the maximum value. This signal type has the advantages of long signal transmission distance and strong anti-interference ability, which is suitable for the scenario that requires long-distance signal transmission.

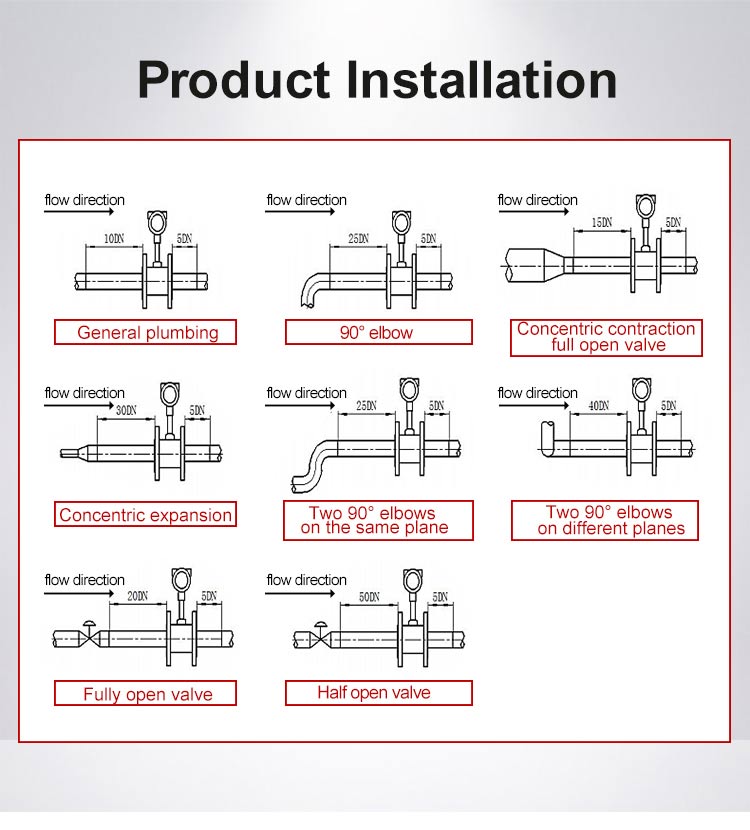

Installation: The installation of vortex flowmeter requires a certain straight pipe section before and after to ensure the measurement accuracy. At the same time, should avoid installation in a strong mechanical vibration, electromagnetic field interference or maintenance is not convenient occasions.

Maintenance: Regularly check the operation status of the flowmeter, including signal output, meter display, etj.. If abnormalities are found, they should be dealt with in time. In addition, attention should be paid to keep the flowmeter clean and dry to extend the service life.

Ne i vlerësojmë reagimet tuaja! Ju lutemi plotësoni formularin më poshtë, në mënyrë që të mund t'i përshtatni shërbimet tona për nevojat tuaja specifike.

Klikoni butonin për të marrë informacione për produktin dhe kuotat në WhatsApp.

MERR CITA

Hetim